The Hidden Costs Of Poor Fleet Maintenance And How To Avoid Them

11 December 2025

5 Mins Read

- What Are The Risks Of Poor Fleet Maintenance?

- 1. The Financial Toll That Creeps Up On You

- 2. Downtime Turns Into A Productivity Spiral

- 3. Energy Waste: The Cost You Don’t See On Paper

- 4. Safety Risks And Compliance Problems

- Proper Fleet Maintenance Ensures Longer Equipment Life, Better Long-Term Planning

- Why Power Choices Matter More Than You Think

You probably already know that poor maintenance can slow a business down, but most people don’t realise how deep the ripple goes until it’s too late. One small delay turns into broken schedules, tired workers, and equipment that suddenly feels older than it actually is.

And sometimes, it starts with the simple things you overlook, like how to choose the right battery for a forklift or when to schedule basic inspections.

These tiny choices seem harmless at first, but they quietly shape how smoothly your operations run day after day.

Furthermore, if you are not particular about the maintenance and repair schedules, the fleet maintenance costs (hidden and the obvious ones) will only shoot up.

In this article, I will talk about how poor fleet maintenance leads to high repair costs and impacts operational efficiency. Overall, missing a maintenance schedule affects your business in the following ways.

- High Repair Cost

- Compromised Operational Efficiency

- Compromised Safety

- Chances of Litigations for Safety Rules Violations.

Here are more details about the risks of poor fleet maintenance and the practical ways to avoid them.

What Are The Risks Of Poor Fleet Maintenance?

As fleet owners, we often forget that we may miss a maintenance schedule, but the Federal Motor Carrier Safety Administration (FMCSA) is maintaining all the records. It is difficult to avoid their vigilance of safety and maintenance issues.

In addition, based on the type of fleet you own, there are different standard operating procedures or SOPs. If we fail to follow that, you will face compliance issues.

Here is more on the disadvantages and the impacts of poor fleet maintenance on a business.

1. The Financial Toll That Creeps Up On You

There’s a strange thing about fleet maintenance: you notice the big breakdowns, but the small issues? They hide. They build up slowly, and they cost you more than you expect.

When a machine starts acting up, it rarely jumps straight to a full shutdown. Instead, it works a little harder. It drains more power. It takes longer to get through a task. You don’t always see the problem in the moment. You feel it later—in repair bills that come out of nowhere or in productivity numbers that dip for reasons you “can’t quite explain.”

A reactive approach always, always costs more. Waiting for something to break means you’re not only fixing the problem, but you’re paying for all the chaos that happened because of it.

Idle workers. Missed deadlines. Temporary rentals you didn’t budget for. These all pile into real money lost.

2. Downtime Turns Into A Productivity Spiral

Downtime doesn’t operate alone. It drags everything with it.

When one machine fails, the rest of your workflow feels the effect. Maybe orders start stacking up. Maybe your team slows down because the process no longer flows the way it should. Also, maybe people become frustrated because they can’t do their jobs as well.

Even a small interruption in one part of your fleet can slow the whole system. That’s the part many businesses miss. It’s not about one forklift or one pallet jack. It’s the entire chain.

And the truth? Most of these slowdowns are preventable. Consistent, thoughtful maintenance keeps your fleet predictable. It keeps your people moving. It protects your schedule from collapsing under pressure.

3. Energy Waste: The Cost You Don’t See On Paper

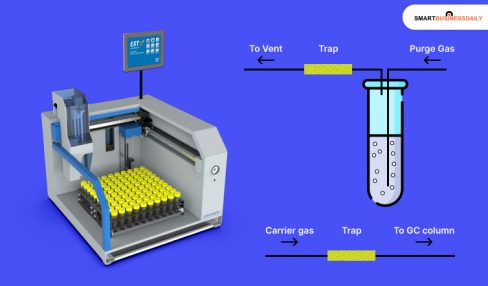

Another hidden consequence of neglect is energy inefficiency. Machines that aren’t maintained properly start consuming more energy, even when performing basic tasks. A forklift with worn parts or poorly managed power sources eats up electricity. A small vibration here, a loose component there—they all push energy usage upward.

Businesses rarely track this kind of waste. But it’s there. And it affects your bottom line more than you think.

4. Safety Risks And Compliance Problems

Poor maintenance doesn’t just cost you money. It can put people at risk.

When equipment isn’t reliable, the workplace becomes unpredictable. Sudden movement! Faulty brakes! Machines powered by unstable components!

All of these create an environment where accidents can happen really fast.

And once safety is compromised, compliance follows. Regulatory issues, investigations, and fines stack on top of whatever repairs you were already dealing with.

Proper Fleet Maintenance Ensures Longer Equipment Life, Better Long-Term Planning

Every machine has a lifespan. But the way you treat that machine determines how long it stays useful.

Regular maintenance keeps your fleet stronger for longer. It prevents early deterioration.

It saves you from having to replace expensive equipment sooner than expected. When your gear lasts longer, your long-term planning becomes clearer, and budgeting becomes easier to control.

Furthermore, you may decide to resell your vehicle one day. If the vehicle is well-maintained and there is a documented history of the maintenance schedule, you will, of course, get a better price.

What Are The Practical Ways To Minimize These Hidden Costs

You don’t solve maintenance problems with one big overhaul. You solve them with consistency.

Having a structured maintenance schedule helps teams stay focused. It makes everything predictable. You avoid surprises because you’re already checking things before they turn into something bigger.

Simple checklists and digital tracking tools make this easier. Teams don’t forget. Nothing gets skipped.

Small habits matter too:

– Cleaning equipment properly.

– Managing charging cycles.

– Inspecting components.

– Catching the little things before they become something costly.

Why Power Choices Matter More Than You Think

One aspect of fleet performance that business owners often downplay is power selection. The batteries, chargers, and energy systems you rely on don’t just turn machines on, but they determine how reliable those machines will be in real operations.

A reliable power source means fewer interruptions. It means predictable performance. It means workers aren’t held back by slow, weak, or inconsistent equipment.

Avoid Hidden Fleet Maintenance Costs By Making Maintenance A Part Of Your Core Strategy

Poor maintenance doesn’t usually show up in one giant moment. It appears in fragments, in the delays, the inefficiencies, the rising energy bills, the tired equipment, and the frustrated teams!

But the good news is simple. You can fix these problems before they grow. When you treat maintenance as a core business strategy instead of a chore, your operations feel different. Your equipment lasts longer. Your people work more confidently.

Overall, by sticking to the right maintenance schedules, you can transform fleet management into a strategic advantage to improve efficiency and profit. It no longer remains a cost center.

Read Also:

Comments Are Closed For This Article